When you think of underground enclosures, “cutting-edge” might not be the first phrase that comes to mind. But Channell is here to change that. With over 90 years of expertise in OSP (Outside Plant) infrastructure, Channell has developed products that not only perform better but also make jobs safer and projects more efficient.

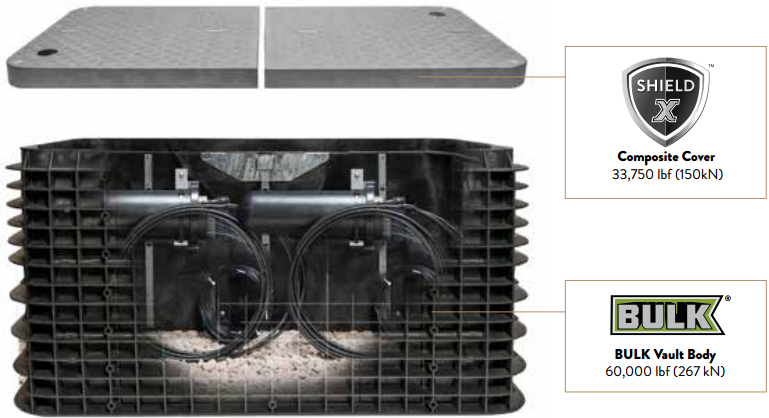

Their BULK and SHIELD technologies are ready to transform the industry, providing smarter alternatives to traditional materials like polymer concrete. Here’s why Channell’s solutions are a game-changer, and how they can make a difference.

Lightweight and Strong: A Win for Safety and Speed

Channell’s BULK enclosures are designed to be tough yet lightweight. Why does that matter?

- For Installers: Traditional materials like polymer concrete are heavy, making installations a time-consuming and injury-prone task. BULK enclosures reduce weight without sacrificing strength, protecting workers from strain and speeding up the job. Many popular size can be lifted by hand under OSHA guidelines, reducing machine costs and logistics.

- For Long-Term Use: Despite being lighter, BULK enclosures handle heavy loads better than many alternatives. This means they can support more weight while lasting longer in the field. The enclosures are ANSI 77 / Tier 22 rated, meeting specifications as required in the field.

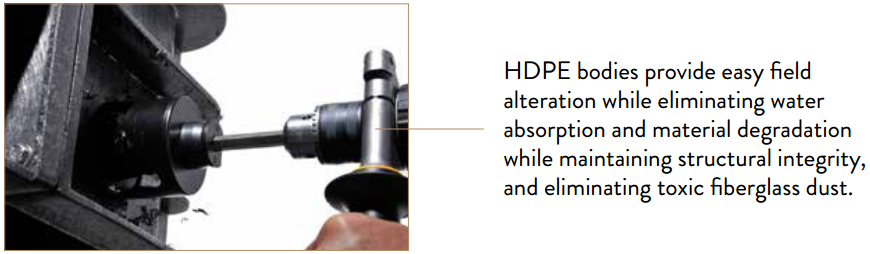

Goodbye Harmful Dust

Goodbye Harmful Dust

Cutting ducts in traditional materials like concrete can release fine dust that’s dangerous to breathe in. With BULK enclosures, that’s no longer a concern.

- Why It Matters: Protecting installers’ health is just as important as finishing the job quickly. Channell’s enclosures ensure a safer work environment by eliminating harmful dust during installation.

Covers That Work Smarter, Not Harder

Channell’s SHIELD covers aren’t just strong—they’re packed with features designed for safety and convenience:

- Super Strength: SHIELD covers meet or exceed 33,750 pounds-force, so they can handle extreme loads without breaking. In fact, large box covers were tested to over 50,000 pounds-force without breaking, far exceeding the industry testing requirements.

- Lighter Design: These covers are up to 70% lighter than cast iron and 50% lighter than polymer concrete. That’s less heavy lifting for the field, reducing the risk of injuries.

- Anti-Slip, Anti-Trip: The patented tread design offers 20% better slip resistance than traditional covers, even exceeding Australia’s AS4586 skid specification (the highest global standard). Whether it’s rainy, muddy, or icy, SHIELD covers help keep everyone safer.

Built to Last

Channell takes durability seriously. Their Endurance Stress Testing (EST™) process measures how SHIELD covers perform over time, ensuring they hold up in the field for years to come.

- Why It Matters: Products that stand the test of time reduce maintenance and replacement costs. That’s value you can count on for the long haul.

Why Choose Channell?

By choosing Channell, you’re not just getting cutting-edge technology—you’re getting peace of mind. Their BULK and SHIELD solutions combine innovation, safety, and performance to meet the demands of modern infrastructure.

If you’re looking to build infrastructure that lasts, delivers value, and meets the highest safety standards, Channell is the partner you need. Contact your Biben Sales associate in PA, South NJ, DE, MD, DC, North VA, or WV to see a sample and learn more about how we can help on your futureprojects.